Four HKPC I&T Inventions Win TechConnect 2023 Innovation Awards

The Hong Kong Productivity Council (HKPC) has garnered a record-breaking of four Innovation Awards at the TechConnect World Innovation Conference and Expo 2023 (TechConnect), which fully recognises HKPC’s world-class R&D capabilities and efforts to promote practical applications and commercialisation of innovative technologies.

Innovation and Description

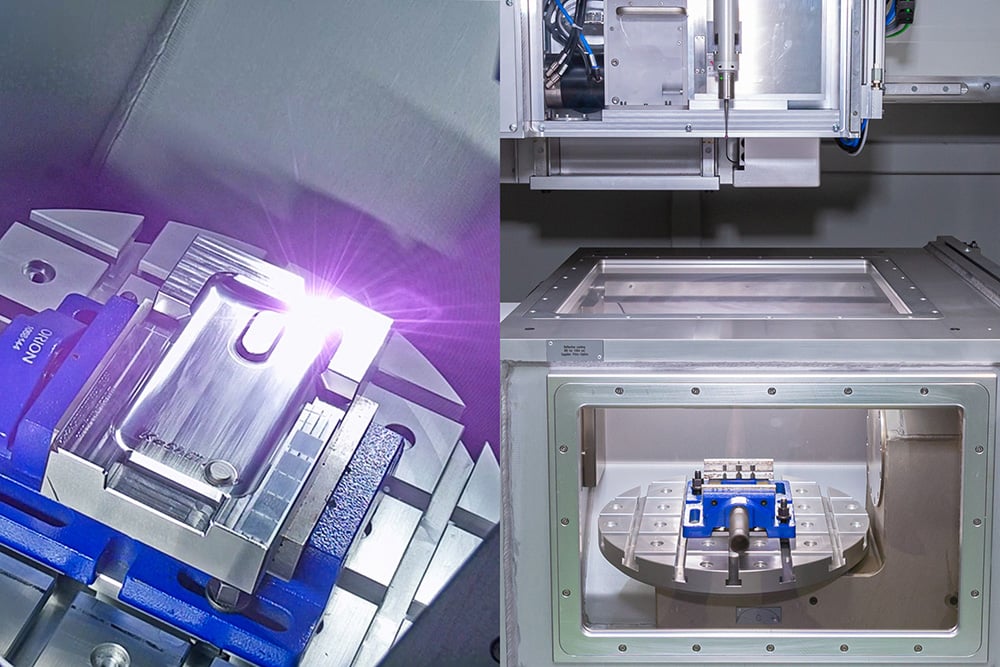

Dual-laser Hybrid Polishing Technology

"Dual-laser hybrid polishing technology" is a combination of aesthetics, accuracy, time-saving, cost-effectiveness, and eco-friendliness. Its core lies in hybrid mode processing of rough polishing by Continuous-Wave lasers and fine polishing with pulsed lasers under a contactless process. A thin layer of material is molten by a laser beam with precisely controllable path, energy, and speed to form a smooth surface, without any material removal. The process not only improves the optical characteristics and corrosion resistance of the component, but also reduces frictional resistance and greatly enhances the appearance of the polished object.

With the funding support from the Innovation and Technology Fund of the Innovation and Technology Commission of the HKSAR Government, the technology has been granted patents both in Hong Kong and the Mainland. The cooperation with manufacturers for the adoption of this technology is in progress, with the objective to enable small and medium-sized enterprises to utilise this technology at a low cost. This R&D project also won the Silver Award at the "2022 Geneva International Exhibition of Inventions."

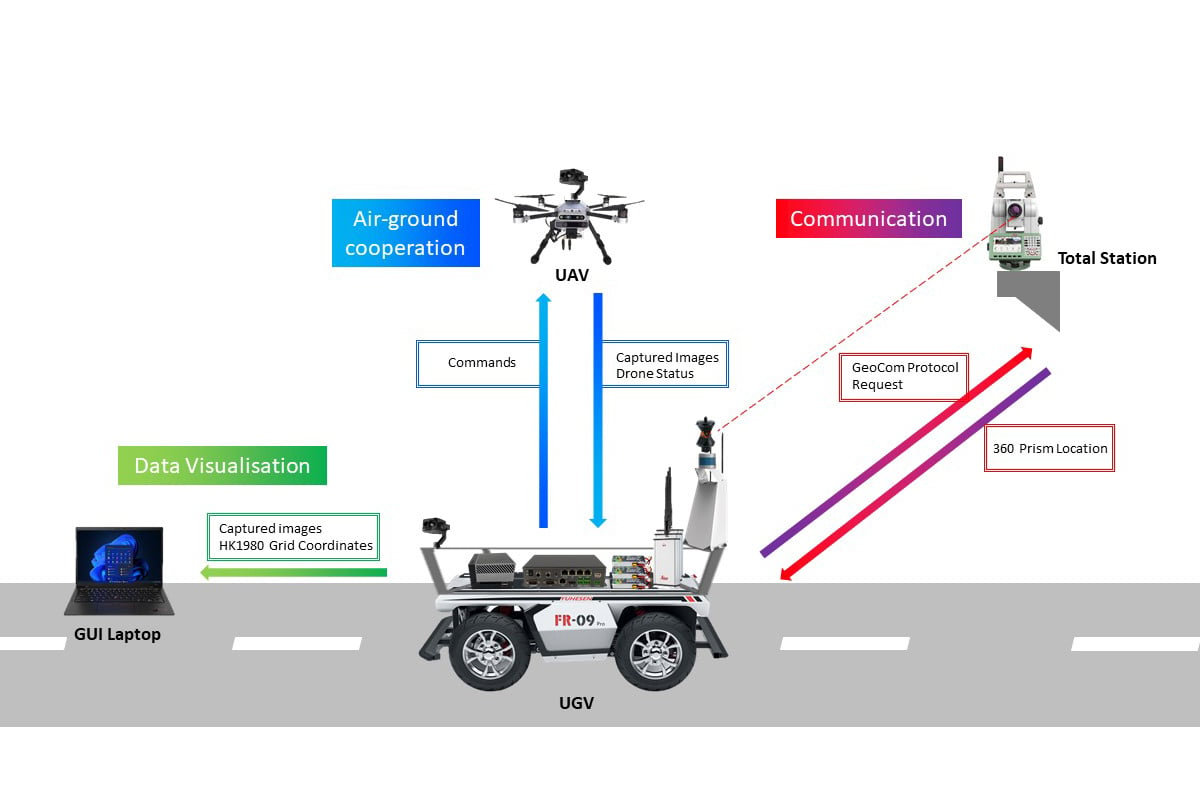

Autonomous Air-Ground Cooperative Tunnel Inspector

The system is Hong Kong’s first air-ground image collection robotic system that brings digital and automatic upgrades to tunnel inspection and maintenance. The system will be applied in the Trunk Road T2 and Cha Kwo Ling Tunnel project. By developing a state-of-the-art multi-robot collaborating system with an Unmanned Ground Vehicle (UGV) and an Unmanned Aerial Vehicle (UAV), the robotic system can autonomously collect high-resolution images of tunnel internal structures including thermal barrier, vitreous enamel panel cladding, and carriageway paving. Without assigning additional workers and substantive working platforms, the intelligent robotic system can automatically collect the images that fully cover the inspection range. In addition, by providing the Hong Kong local coordinates of the captured images, the quality of the finished tunnel internal structures can be documented and digitalised for easy asset management, thus providing an automatic and intelligent upgrade to the quality monitoring system for efficient tunnel maintenance.

Collaboration partners: East Development Office (EDO) of the Civil Engineering and Development Department (CEDD) of the HKSAR Government, and Hyder-Meinhardt Joint Venture

Anomaly Recognition Graphical Universal System (ARGUS)

An AI defect inspection system with a 3D camera on a robot arm designed for quick deployment in various production lines and products. Minimal data is required for AI training.

The name ARGUS came from Argus, the many-eyed giant in Greek mythology, who is said to be able to watch from all directions with more than 100 eyes. The ARGUS solution steps further by not only inspecting complex objects from all-around views with nimble “hands” (collaborative robotics) but also detecting tiny defects on a surface with intelligent “eyes” (high-resolution cameras). Then, the smart “AI brain” of ARGUS finds the best views of the products autonomously and explores unknown flaws by unsupervised learning from limited good products to achieve smart quality inspection of automotive parts.

ARGUS has been granted patents both in Hong Kong and the Mainland. The R&D team will continuously improve the detection accuracy, thereby improving product quality, saving labour costs, and accelerating product flow. This project also won the Silver Award at the "2023 Geneva International Exhibition of Inventions."

Collaboration partners: Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR), and Pro-Technic Machinery Ltd

Interactive Control System for Robot Manipulation with AR Technology

The technology involves intuitive interaction through AR glass so that the human operator can monitor as well as control the industrial robot arm both on-site and remotely. Robotic tasks can be demonstrated by humans in the augmented reality environment and the skill can be transferred directly to the robot arm for task execution.

The technology provides a new complementary framework for human-robot collaboration that balances the safety of humans and the efficiency of robots. The robot carries out given tasks using a vision-based adaptive controller, and the human operator collaborates with the robot in the null space. Additionally, the robot can simultaneously learn the expert's demonstration in task space and null space beforehand with dynamic movement primitives (DMP). Human demonstration and involvement are enabled via augmented reality (AR) devices, achieving simple and efficient data collection from demonstration.

Collaboration partners: Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology (co-founded by HKPC, Department of Automation, Tsinghua University, and Research Institute of Tsinghua, Peral River Delta), and FLAIR